Miniaturized Enzymatic Assays with Glycerol

The Echo liquid handlers incorporate Dynamic Fluid Analysis to optimize acoustic transfer on-the-fly. Starting with a default setting for a broad fluid class, each transfer is further optimized in real-time to account for various changes in fluid properties. This enables accurate and precise transfer of reagent sets that may contain surfactants or glycerol, which would require multiple calibrations on traditional liquid handlers. This application highlight discusses the capability of the Echo liquid handlers to transfer low volumes of enzyme stored in 50% (v/v) glycerol into 384-well plates. This allows both the simplification of protocols by removal of an intermediate dilution step, and improved performance in a miniaturized format.

- Miniaturize enzymatic assays to save reagent cost

- Remove chances of intermediate dilution errors

- Contamination-free reagent and sample transfer

- Eliminate pipette tips and washing to save consumables cost and waste

Miniaturized Enzymatic Assays

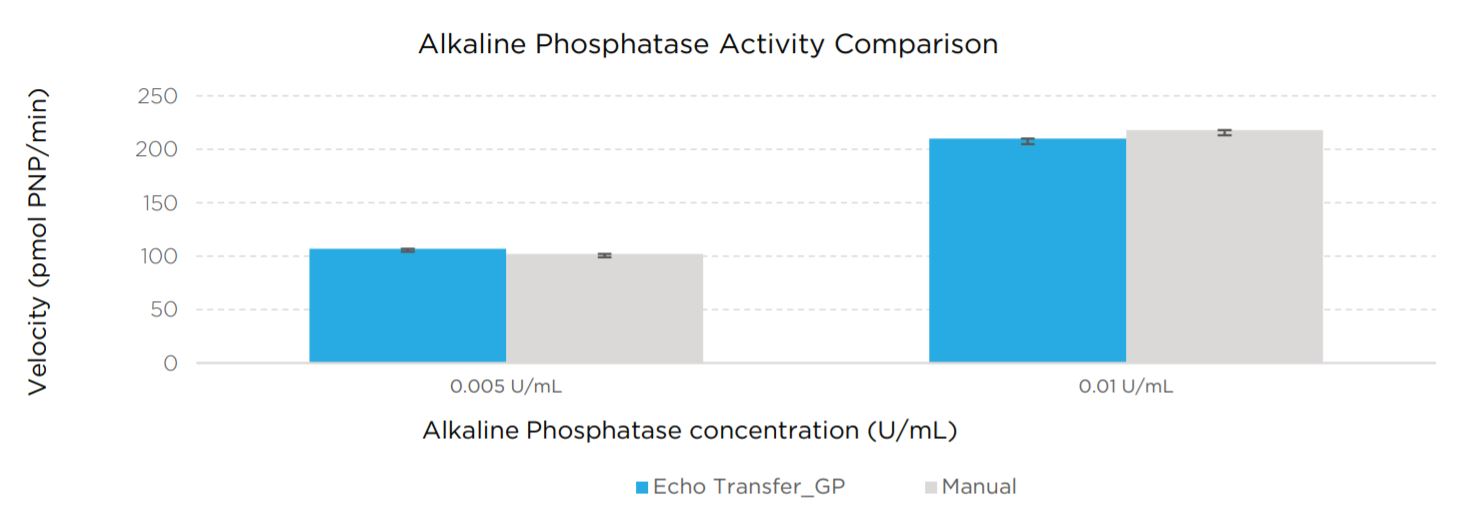

Favorable comparison between 10 μL diluted enzyme (grey bars) and 25 or 50 nL enzyme transfers performed by the Echo liquid handler (light blue bars).

| Echo Transfer | Manual Transfer | |||

| 384PP_AQ_GP (25 nL transfer) | 384PP_AQ_GP (50 nL transfer) | 10 μL | 10 μL | |

| 0.005 U/mL | 0.01 U/mL | 0.005 U/mL | 0.01 U/mL | |

| Avg. Velocity | 107.82 | 215.15 | 103.58 | 222.73 |

| Std. Deviation | 2.68 | 6.29 | 2.3 | 4.56 |

| CV | 2.5% | 2.9% | 2.2% | 2.0% |

Simplified Workflows with Concentrated Enzymatic Transfer

Many biological reagents are shipped and stored with a cryoprotectant such as glycerol present. The generation of working stocks and serial dilution for standard curves is an assumed part of everyday lab operations. The Echo liquid handler enables the removal of these manual dilution steps. This can have the additional benefit to allow further miniaturization of assays by enabling direct transfer of reagents containing high concentrations (up to 50% v/v) of glycerol. Incremental transfers of 2.5 nL are performed accurately and precisely regardless of glycerol concentrations.

Traditional Methods. Enzymes are often shipped with cryoprotectants such as glycerol which stabilizes enzymes for storage. Traditional methods require dilution of enzymatic stocks, partly due to inaccuracies of pipetting concentrated stocks. The additional dilution step is a potential source of error and limits the lifetime of the diluted enzyme.

Echo enabled methods. The Echo liquid handler uses Dynamic Fluid Analysis to sense differences in surface tension and viscosity in real time. The capabilities allow transfer of enzyme in high concentrations of cryoprotectant, removing a potential error sources and preserving enzyme stability for a longer period of time.

The Echo 500 series revolutionizes liquid transfer by using acoustic energy to eject fluids. The Echo liquid handler is completely touchless—no tips or nozzles, and no material contacts the same as it moves from source to destination. Low-volume, accurate and precise transfer at volumes of 2.5 nL and up allow for assay miniaturization to previously unattainable volumes. Acoustic transfer is compatible with a wide range of fluid types, enabling high-throughput total assay assembly for applications including biochemical assays, qPCR, and protein crystallography. Transfer of samples from any well of a source to any destination further minimizes sample consumption and simplifies assay setup and execution.